In a highly competitive market, the importance of brand image is self-evident. As one of the bridges connecting brands and consumers, laser marking is winning the favor of many enterprises with its unique charm.

Revealing the unique charm of laser cloth label: why it has become the first choice of modern brands

Compared to traditional printed labels, laser-engraved labels are not only more delicate and delicate, but also have extremely high durability. They can withstand repeated washing without fading or deformation, thus transmitting the brand information for a long time.

At the same time, this technology allows highly personalized customization program, whether it is a complex logo or exquisite text typesetting, can be perfectly presented.

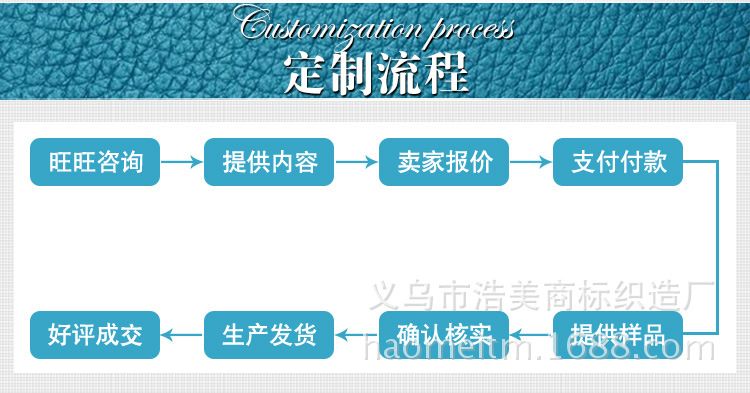

From Zero to One: Understanding the Whole Process of Laser Labelmaking

Behind every successful laser marking is a series of precise operation steps. First of all, the designer will draw the first draft according to the customer's requirements, and then carry out digital conversion processing after confirmation so that the subsequent processing equipment can identify and read the data. The next step is to select the appropriate fabric-usually there are polyester, nylon and other options to choose from-and then send it to the advanced laser cutting machine to complete the workflow of the final product forming stage.

How to choose the best material and process for your brand

Different application scenarios require the use of appropriate types of materials and technical means to achieve the best results. For example, for sportswear, it may be more likely to use webbing styles that are light, breathable and easy to fix the installation position. For the small card form attached to the luxury packaging box, it pays attention to the thick, luxurious atmosphere and bronzing decoration to add a high-level atmosphere, etc.

Case Study: How Famous Brands Stand Out With Laser Labeling

Many internationally renowned names have long been aware of this and have used it to the fullest. For example, a luxury leather goods manufacturer has added a micro LOGO logo to the end of its wallet zipper to distinguish ordinary models and increase added value, while also allowing consumers to distinguish the authenticity at a glance and buy without worry.

Frequently Asked Questions: Those Things About Customizing Laser Labors

many people who come into contact with this kind of business for the first time will have such confusion: "will it be too expensive for my order quantity to be small?" "how long is the delivery cycle?" in fact, these problems are very normal and there is no need to worry at all because we always adhere to the principle of creating the best interests for customers, flexibly adjust the quotation mechanism and try our best to shorten the waiting time to ensure a satisfactory experience throughout the whole process!

Looking to the future: What industry trends will laser labeling lead

with the continuous development and progress of science and technology and the increasing improvement of people's aesthetic concept, I believe there will be more innovative breakthroughs in the near future, which will make this ancient technique glow with new life and shine with splendor, illuminate the infinite possibilities of the whole textile field and even the wider space waiting for us to explore and discover!